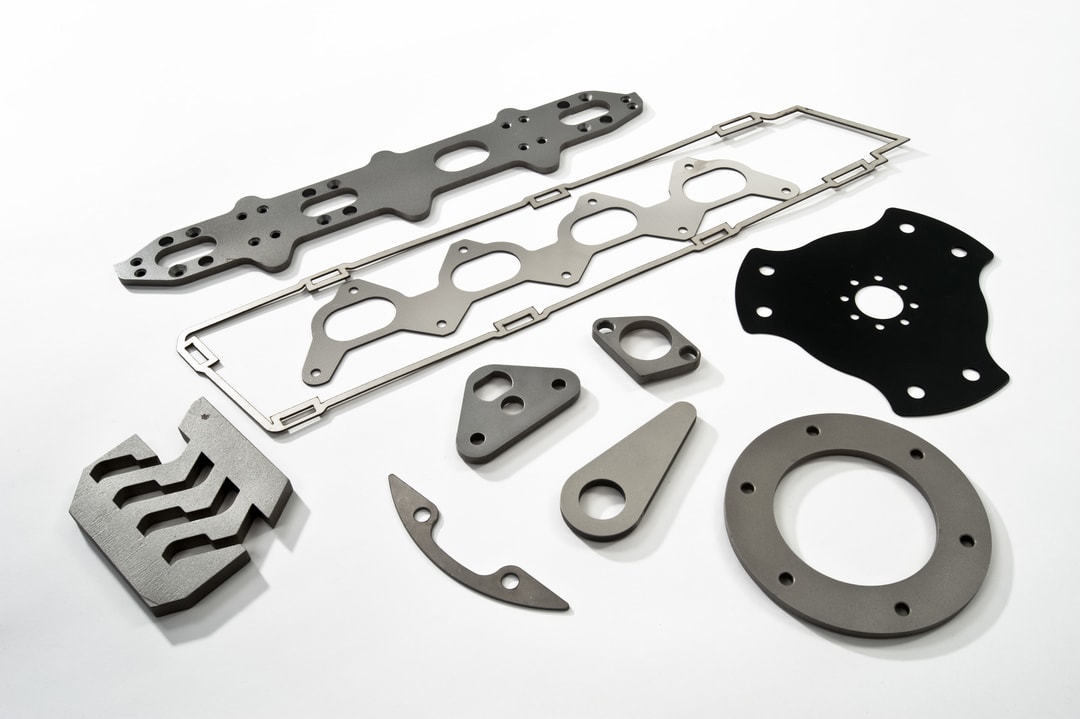

Our CO2 Laser Cutting Capabilities

CO2 laser cutting is a more traditional laser cutting technique, which utilises a high-powered laser beam, typically generated by a carbon dioxide gas mixture, to cut materials. C02 laser cutting is capable of cutting thick materials, making it suitable for a wide range of projects.

CO2 laser cutting is an accurate and time-efficient method of cutting metals, with great cutting power. However, since the introduction of fibre technology, CO2 laser cutting has become less active, although it still remains a prominent method.

Subcon Laser is dedicated to the continual improvement of our business, and we do so through investing in the latest technology; this means our business largely specialises in fibre laser cutting. For a versatile and flexible offering, however, we maintain our CO2 laser cutting department, ensuring our clients receive a service that is truly built around them.

With our industry knowledge and experience, the Subcon Laser team are equipped to handle all types of projects, of all sizes and complexities, and across all industries. We work closely with our customers, establishing your needs during initial conversations and being able to meet them throughout our comprehensive service – from laser cutting to secondary operations and metal finishing.

CO2 Laser Cut Materials

Our CO2 laser cutting operation is suitable for the cutting of:

- Steel.

- Aluminium.

- Stainless Steel.

- Plastics.

- Non-Metallics.

- Others on request.

However, Subcon Laser specialises in the handling of a wide variety of metals, which can be completed by our fibre-cutting service.

CO2 vs Fibre Laser Cutting

Utilising both CO2 and fibre technology enables Subcon Laser a greater scope to take on our clients’ cutting requirements.

The main difference between the two technologies is the laser source and wavelengths the respective machines produce. CO2 laser cutting utilises a carbon dioxide mix to generate the laser source, whilst fibre laser cutting uses an optical fibre. Fibre laser cutters operate at a shorter wavelength, indicating a higher energy.

Fibre laser cutters are suitable for cutting both thinner and thicker materials, and can cut a wide range of metallic materials. On the other hand, CO2 lasers can cut a wide variety of materials, including non-metals.

At Subcon Laser, our range of laser cutting technology, including both state-of-the-art fibre and CO2 laser cutting machines, means we can determine the right production method for your project, combining efficiency with quality.

For more on our fibre laser cutting, see our fibre laser cutting service.