Our Capabilities

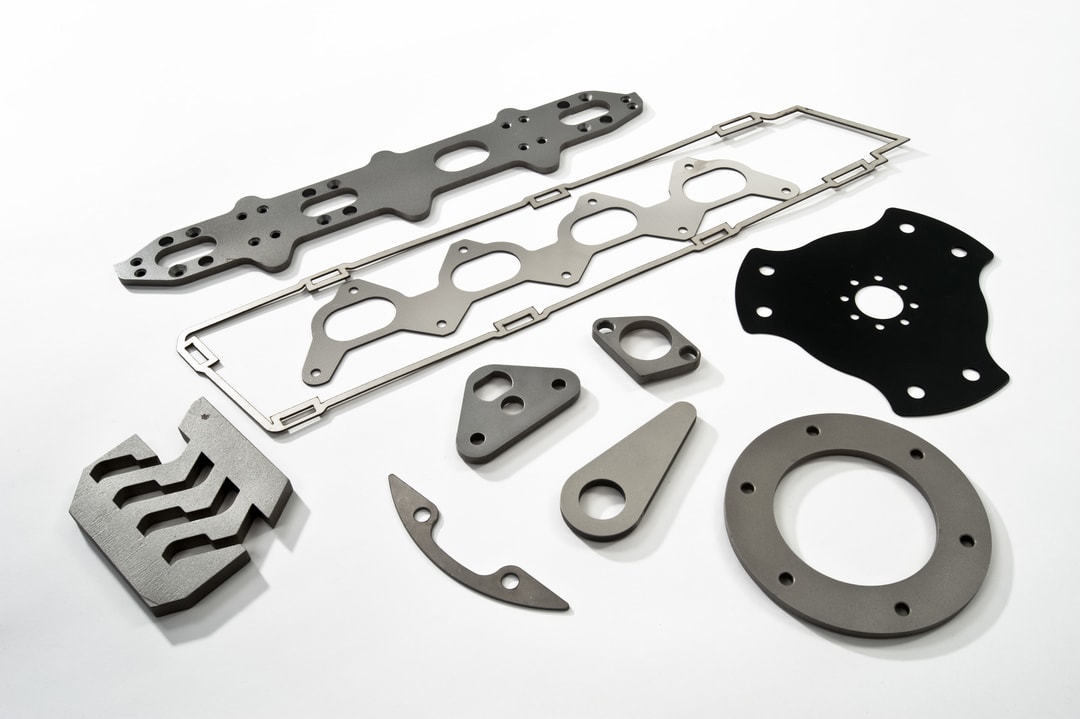

Designed to meet the varied needs of a range of industries, from automotive to power generation, our fibre laser cutting service provides a flexible and proficient offering, taking advantage of the latest machinery. Our technology and plant include CAM/CAD equipment, streamlining production processes from design stages through to full production.

We can do this for standard material sizes:

- 2000mm x 1000mm

- 2500mm x 1250mm

- 3000mm x 1500mm

- 4000mm x 2000mm

- Non standards on request

And material thickness from 0.25mm to 50mm dependent on material type.

We maintain tight tolerances, varying from +/- 0.12mm to +/- 0.5mm depending on material thickness.

Our processes outside of laser cutting include secondary operations, such as bending, laser bevel cutting, weld preps, welding, and much more. We can also provide a range of metal finishing options.

The experienced Subcon Laser engineering team can determine whether fibre is the right technology for your project. Fibre laser cutting offers many advantages, which you can find listed below.

Fiber Laser Cutting Equipment

Fibre laser cutting is regarded as industry leading equipment, being a fast, economic and precision method of cutting.

Subcon Laser has invested in fibre technology to support our laser cutting capabilities due to the proven potential of the machinery. Our machinery includes Trumpf technology, the capabilities of which are increased by auxiliary features and options:

- Nanojoints – Eliminates the need for micro-joints in sheet metal, which would require reworking.

- CoolLine – CoolLine prevents mild steel from melting excessively during the laser cutting process.

- EdgeLine Bevel – Creates chamfers, indentations, and rounds edges on laser cut components.

- Active Speed Control – Ensures the correct feed rate through sensor monitoring to minimise disruption and waste.

Why Choose Fibre Laser Cutting?

Fibre laser cutting achieves high cutting speeds and great precision, making it suitable for a range of materials and material thicknesses, including thin sheet and reflective materials such as brass and copper.

Fibre lasers are easily integrated into automated systems, enabling our CAD/CAM capabilities to be used to their full extent. This improves productivity and our control over quality, resulting in accurate cuts even on complex projects.

Fibre lasers are energy efficient, for cost-savings during production as well as being environmentally considerate.

Alongside fibre laser cutting, we can further provide CO2 laser cutting. Our capabilities for each of these methods ensures our customers benefit from utilising the most efficient cutting method for their project specifications, based upon impartial advice by our engineering team.